Corvettes have always been made of lightweight materials – from the first C1 model built in 1953 with its fiberglass body, to today’s C7 sporting bits of carbon fiber throughout. The absence of useless weight is key.

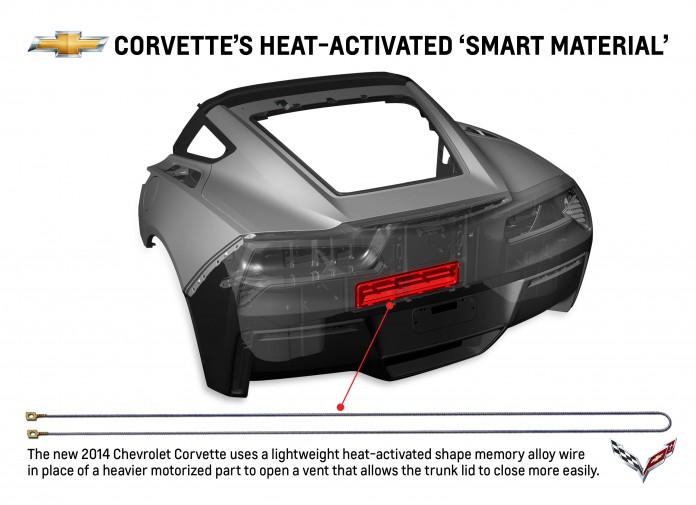

Engineers at Chevrolet have been busy developing innovative ways to save ounces everywhere they could. Once such example is the Corvette’s new rear hatch vent made from shape memory alloys.

The new smart material changes shape when activated by electrical voltages and heat. When activated, a wire made of this smart material contracts and moves a lever arm to open the vent, allowing the trunk lid to close more easily. Once the trunk lid is closed, the electrical current switches off, allowing the wire to cool and return to its normal shape, which closes the vent to maintain cabin temperature.

Using this type of technology eliminates the electric motor actuator, which can number close to 200 in a typical vehicle. Chevrolet has the potential to see some significant weight savings by replacing even a few electric actuator motors.